We use the technique of virtual prototyping and reverse engineering. This is connected with model experimental verification in hydraulic laboratory.

Virtual prototype is given by 3D model from hydraulic design to construction design and manufacturing.

This enables:

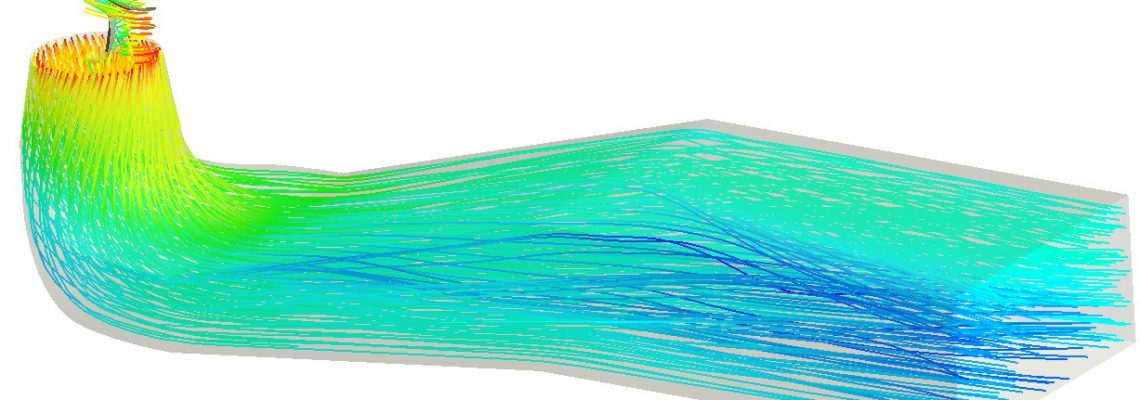

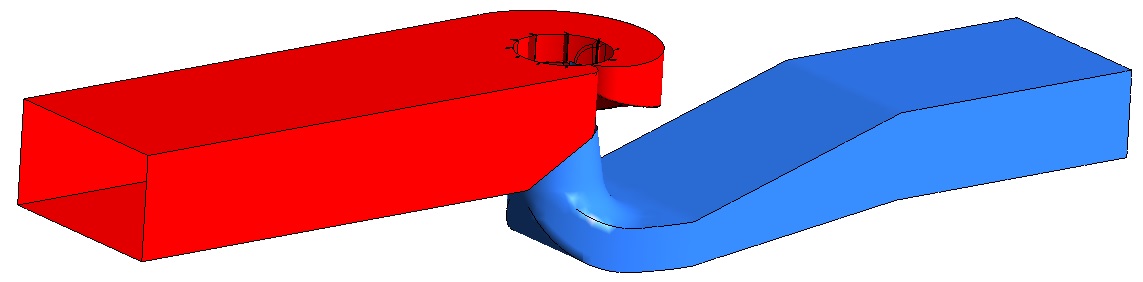

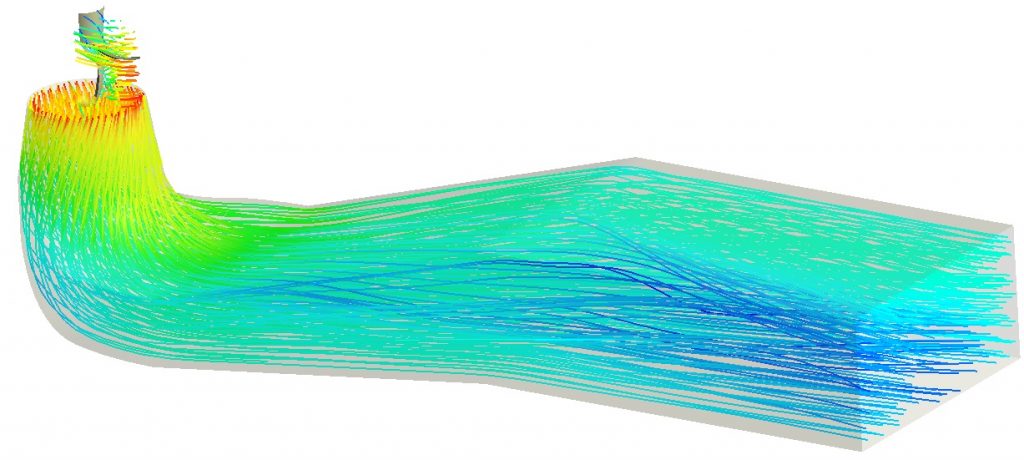

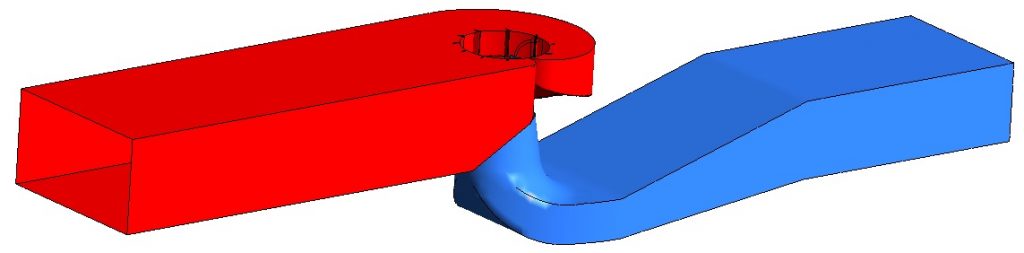

- design of the water machinery parts by means of CFD simulation,

- advanced design supported by FEM simulation with feed back to the design,

- programming CNC machines.

In this way we optimize a machine and fulfil requirements of a new or refurbished machine.

By means of virtual prototyping and reverse engineering we are able to evaluate an increase in efficiency and power output of a refurbished turbine already at the phase of an offer.

Kaplan turbine virtual prototype.

Kaplan turbine virtual prototype.

Čeština

Čeština Español

Español